Brief Introduction

The single layer glass reactor is a generic term for a type of vessel widely used in the process industries. It is used for a variety of process operations such as dissolution of solids, product mixing, chemical reactions, batch distillation, crystallization, extraction and polymerization. The advantages of the glass reactor lie with its versatility and visibility.

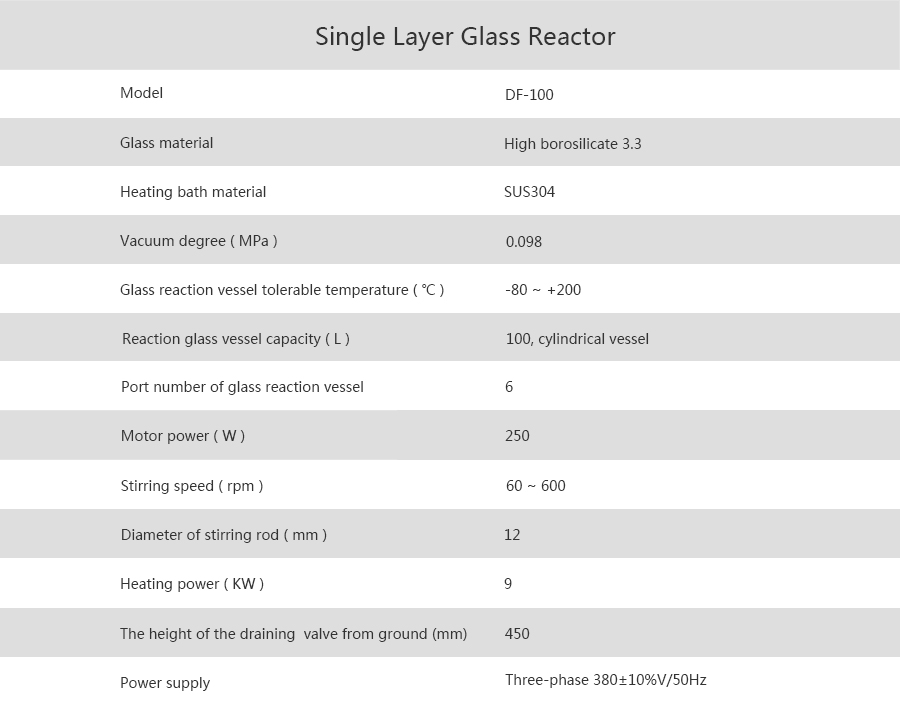

The single layer glass reactor is equipped with the stainless steel 304 bath, and add water or oil to heat the reaction glass vessel directly. The experiment can be completed at constant-temperature condition. It is very convenient and easy to operate.

Features

1. Overall stainless steel frame and screw with strong support and hardness

2. All glass parts adopt high borosilicate glass 3.3 with good physical and chemical properties.

3. Wide working temperature range: -80℃ to 200℃.

4. Zero dead space anticorrosive draining valve. solids / liquid material can be easily released from below.

5. Stainless steel stirring rod covered with PTFE outside

6. Imported high torque reinforcement electrical machine, frequency conversion constant temperature stirring system, stable working state.

7. Equipped with the lockable casters, and it is convenient to move or fix.

8. Distillation and reflux can be carried out at the same time.

9. Ex-proof motor is optional for 10L,20L,30L,50L,100L,150L,200L .